When someone visits our mill for the first time, the reactions are usually the same—wide eyes, a bit of awe, and the occasional “so this is how fabric is made?” And honestly, it’s fair. Watching hundreds of threads crisscross at lightning speed to create a solid piece of fabric feels like watching something come to life.

At the heart of it all is the woven fabric machine. Without it, there would be no shirting, no jackets, no curtains, and no fashion lines. Yet, this machine doesn’t often get talked about unless you’re knee-deep in manufacturing.

But if you work in sourcing, design, or development, knowing how these machines work—and why they matter—can make a real difference when picking the right fabric for your brand.

So, What Does a Woven Fabric Machine Actually Do?

Think of it like this: a woven fabric machine is where raw yarn becomes real fabric. It takes two sets of yarns—the long ones running down the roll (called warp) and the ones going across (called weft)—and weaves them together to form the textile you end up using.

There are different types of machines, each with their own way of handling the process. Some are better for high-volume basics, others for specialty weaves. The type of machine used influences not just how the fabric looks, but how it performs, how quickly it can be made, and sometimes, even how much it costs.

Types of Woven Fabric Machines You Should Know

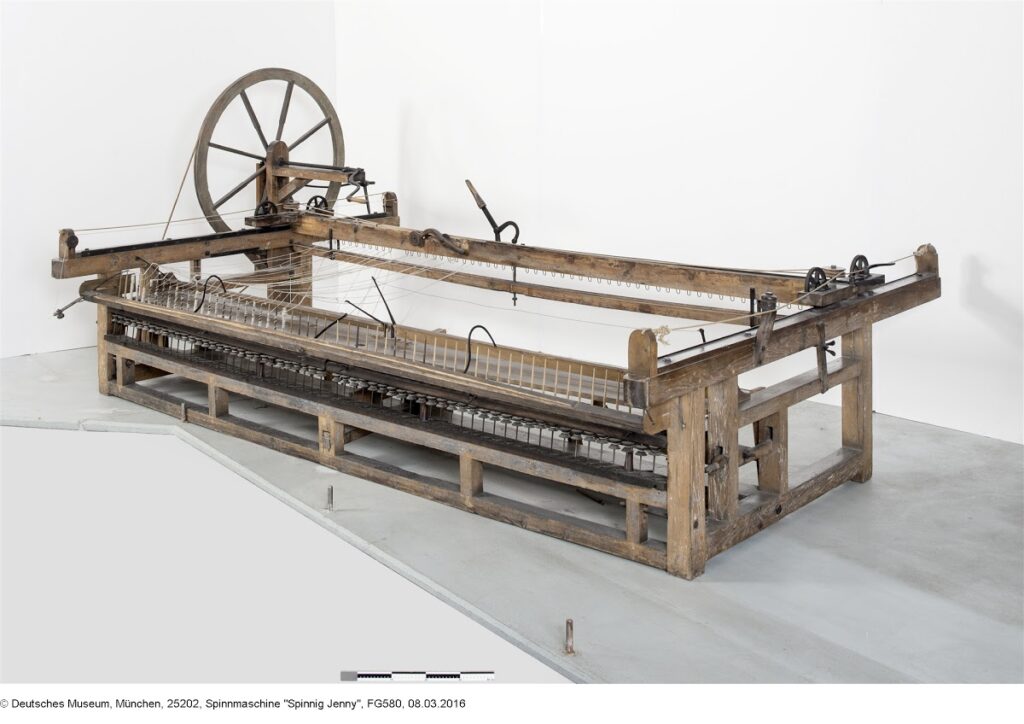

Shuttle Loom

This is the old-school version. It’s slower, makes a distinctive edge on the fabric, and is often used for vintage-style or heavyweight fabrics.

Rapier Loom

This one uses a little arm (like a sword, or “rapier”) to move the yarn across. It’s precise and versatile, which makes it popular in modern mills.

Air Jet Loom

As the name suggests, it uses air to blast the yarn across. It’s fast, efficient, and best for lightweight fabrics like cotton shirting or poplin.

Water Jet Loom

This machine works a lot like the air jet, except it uses water. It’s mainly used for synthetic yarns, since natural fibers can shrink or react to water.

Jacquard Loom

This one’s for the creative stuff. It lets you weave detailed patterns straight into the fabric. Think florals, geometrics, or textured logos.

Why the Machine Matters More Than You Think

It’s easy to assume that fabric is fabric, no matter how it’s made. But the machine behind it plays a big role in how it looks and feels. Some fabrics need a tight weave to hold structure. Others rely on the loom’s ability to handle fine yarns for that soft, fluid drape.

And for the business side of things—like lead times and cost—machine type matters a lot. Air jet looms can churn out meters quickly, while jacquard looms take more time. So if you’re planning a drop and your supplier suggests a different base fabric, they might be factoring in the loom’s capability without saying it outright.

What It’s Like at Our Mill

At Dinesh Exports, we work with a mix of modern machines depending on the collection. Some of our designs need the structure and finish that comes from a rapier loom. Others, like our breezy flax blends or dobby textures, are better suited to slower looms that give more texture.

We don’t expect buyers or designers to know all the technical details, but when someone asks about the process, we love walking them through it. The sound of the looms running, the rhythm of threads moving—it’s something you never forget once you see it in person.

Read more about woven fabric machines here.

Tips for Buyers and Designers

If you’re sourcing woven fabrics, here are a few things to keep in mind:

- Ask about the loom. You don’t need to be technical, but just knowing the type gives you clues about durability, cost, and lead time.

- Understand the edge finish. Fabrics made on shuttle looms often have a stronger edge, which may matter for unlined garments or visible seams.

- Don’t ignore the texture. Some machines produce a tighter weave, while others allow more softness and drape.

- Timeline matters. High-volume air jet fabrics might ship sooner than a custom jacquard weave.

In Closing

Woven fabric machines might not be the most glamorous part of textile manufacturing, but they’re the backbone. They take simple yarns and give them structure, shape, and purpose. Whether it’s a clean white shirt or a patterned dress, it all starts here.

And for anyone working in sourcing or product development, a little insight into how that fabric was made can go a long way. It helps you ask better questions, avoid delays, and choose materials that match your vision.

If you’re curious to learn more, we’re always happy to show you what’s running on the looms this week, simply contact us here.